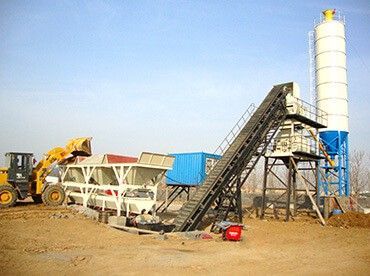

YHZS75 Mobile Concrete Batching Plant

PLC brand: SIMENS/OMRON

Electrical components: Relays, contactors, etc. SCHNEIDER make

Control console: Buttons, lamps, indicators, etc.

Air conditioner: 1 unit, GELI brand

Printer: 1 unit, EPSON or equivalent

Computer with control software: 1 unit

Description

The Features of YHZS75 Mobile Concrete Batching Plant:

01

YHZS75 mobile concrete batching plant is a compulsory, high efficient equipment to produce plastic, dry and wet concrete, etc. It is widely used in large and medium-sized construction, road and bridge engineering, the production of commercial concrete ideal equipment.

02

JS1500 twin-shaft concrete mixer is adopted in this series, With a homogeneous good mixing performance, this plant can produce 75 cubic meters of concrete per hour.

03

It uses the latest design ideas of electronic weighing, computer control digital display control technology, electronic volume with buffer device and automatic compensation function, high accuracy.

04

The aggregate system uses a large belt width herringbone material with boardwalk, which is the ideal choice for the majority of the construction to produce high quality concrete.

05

Dynamic display on a computer screen process, plant operators can easily change the concrete recipes, making sure the parameters are accurate and reliable.

Parameter

| Model | YHZS75 |

| Output capacity | 75m³/h |

| Overall power | 105kw |

| Discharge height | 3800mm |

| Max. hauling speed | 40km/h |

| warranty | 13months after commissioning |

| After-sale service | Guidance on erecting, commissioning and operator training, 24/7 technical assistance afterwards |

| Concrete mixer | JS1500 |

| Motor power | 30kw×2 |

| Mixing circle | 60s |

| Discharge volume | 1500L |

| Max. aggregate dia. | 80mm |

| Aggregate batcher | PLD2400 |

| Storage hopper | 2, 3 or 4 sorts |

| Weighing hopper | 2400L |

| Aggregate weighing precision | ±2% |

| Aggregate feeder | Belt conveyor |

| Cement | ±1% |

| Water | ±1% |

| Additive | ±1% |

| Control system | Auto computer control, 1 set |

| PLC brand | SIMENS/OMRON |

| Electrical components | Relays, contactors, etc. SCHNEIDER make |

| Control console | Buttons, lamps, indicators, etc. |

| Air conditioner | 1 unit, GELI brand |

| Printer | 1 unit, EPSON or equivalent |

| Computer with control software | 1 unit |

| Uninterrupted Power Supply | 1 unit |

| Pneumatic system | 1 set |

| Air-compressor | 0.6MPA |

| Triplet(oil-water separator) | 1 set with a back-up spare |

| Solenoid valve | 1 set with multiple contactor coils |

| Documentation | 1 set |

| Spare parts | included |

| Operation guide | included |

| Maintenance brochure | included |

| Electrical diagram/circuit | included |

-

HZS25 Compact Concrete Batch Plant

HZS25 Compact Concrete Batch Plant

view detail -

HZS60 Stationary Concrete Batch Plant

HZS60 Stationary Concrete Batch Plant

view detail -

HZS90 Stationary Concrete Batch Plant

HZS90 Stationary Concrete Batch Plant

view detail -

YHZS25 Mobile Concrete Batching Plant

YHZS25 Mobile Concrete Batching Plant

view detail -

YHZS60 Mobile Concrete Batching Plant

YHZS60 Mobile Concrete Batching Plant

view detail -

YHZS100 Mobile Concrete Batching Plant

YHZS100 Mobile Concrete Batching Plant

view detail -

Super-Mobile Asphalt Mixing Plant

Super-Mobile Asphalt Mixing Plant

view detail -

Asphalt Drum Mixing Plant

Asphalt Drum Mixing Plant

view detail -

Asphalt Batch Mixing Plant LB Series

Asphalt Batch Mixing Plant LB Series

view detail

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.