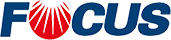

YHZS100 Mobile Concrete Batching Plant

PLC brand: SIMENS/OMRON

Electrical components: Relays, contactors, etc. SCHNEIDER make

Control console: Buttons, lamps, indicators, etc.

Air conditioner: 1 unit, GELI brand

Printer: 1 unit, EPSON or equivalent

Computer with control software: 1 unit

Description

The Features of YHZS100 Mobile Concrete Batching Plant:

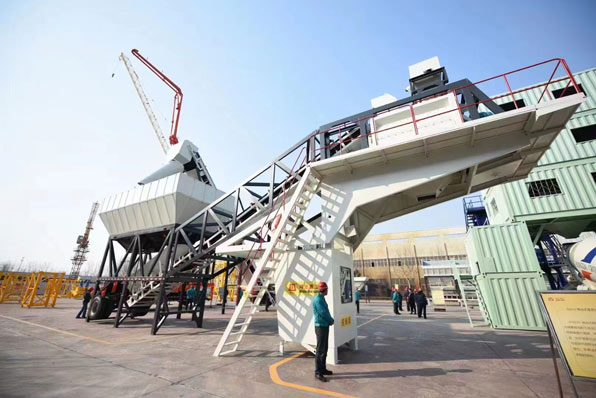

Absorbing technologies from different countries, FOCUS MACHINERY presents the world one and only YHZS100 mobile type concrete mixing plant.

SICOMA concrete mixer is adopted, the lubrication system of which adopts advanced centralized oil lubricating system, convenient for oil supplying. This system is equipped with over-votage warning and low oil level warning, safe and reliable.

Although this plant has the impressive output capacity of 100m3 per hour, it still has the characters as all other mobile plants:

01

Fast disassembly and assembly, convenient movement

Except for external equipment such as screw conveyors and cement silos, all the wiring of the mixing station does not need to be disassembled, and only a 30-ton crane is required to disassemble and shift in one day. During installation, if the ground is flat and solid, no foundation is needed, and production can be done on the same day, which is very suitable for units with tight schedules. The station is equipped with tires and towing pins, alowing a maximumspeed of 60 kmh when towed by a trailer. The total weight of all equipment in the mixing station is 23.5 tons, and all accessories are removed at one time with the station.

02

Excellent mixing performance

Using a forced twin-shaft mixer, the shortest mixing time can be used to achieve uniform mixing. For dry hard, semi-dry hard, plastic and various proportions of concrete can complete good mixing.

03

High-end configuration, high reliability, accurate measurement and convenient operation

The main electrical components of the mixer, the metering sensor, and the control system are all impoted components, which not only greatly reduces the failure rate of the equipment, but also improves the metering accuracy of the equipment. The whole machine adopts computer control, which can be operated automatically or manually. The operation is simple and easy to master

Parameter

| Model | YHZS100 |

| Output capacity | 100m³/h |

| Overall power | 140kw |

| Discharge height | 3800mm |

| Max. hauling speed | 40km/h |

| warranty | 13months after commissioning |

| After-sale service | Guidance on erecting, commissioning and operator training, 24/7 technical assistance afterwards |

| Concrete mixer | JS2000 |

| Mixing circle | 60s |

| Discharge volume | 2000L |

| Max. aggregate dia. | 80mm |

| Aggregate batcher | PLD3200 |

| Storage hopper | 2, 3 or 4 sorts |

| Weighing hopper | 3200L |

| Aggregate weighing precision | ±2% |

| Aggregate feeder | Belt conveyor |

| Cement | ±1% |

| Water | ±1% |

| Additive | ±1% |

| Control system | Auto computer control, 1 set |

| PLC brand | SIMENS/OMRON |

| Electrical components | Relays, contactors, etc. SCHNEIDER make |

| Control console | Buttons, lamps, indicators, etc. |

| Air conditioner | 1 unit, GELI brand |

| Printer | 1 unit, EPSON or equivalent |

| Water | ±1% |

| Computer with control software | 1 unit |

| Uninterrupted Power Supply | 1 unit |

| Pneumatic system | 1 set |

| Air-compressor | 0.6MPA |

| Triplet(oil-water separator) | 1 set with a back-up spare |

| Solenoid valve | 1 set with multiple contactor coils |

| Documentation | 1 set |

| Spare parts | included |

| Operation guide | included |

| Maintenance brochure | included |

| Electrical diagram/circuit | included |

-

HZS25 Compact Concrete Batch Plant

HZS25 Compact Concrete Batch Plant

view detail -

HZS60 Stationary Concrete Batch Plant

HZS60 Stationary Concrete Batch Plant

view detail -

HZS90 Stationary Concrete Batch Plant

HZS90 Stationary Concrete Batch Plant

view detail -

YHZS25 Mobile Concrete Batching Plant

YHZS25 Mobile Concrete Batching Plant

view detail -

YHZS60 Mobile Concrete Batching Plant

YHZS60 Mobile Concrete Batching Plant

view detail -

YHZS100 Mobile Concrete Batching Plant

YHZS100 Mobile Concrete Batching Plant

view detail -

Super-Mobile Asphalt Mixing Plant

Super-Mobile Asphalt Mixing Plant

view detail -

Asphalt Drum Mixing Plant

Asphalt Drum Mixing Plant

view detail -

Asphalt Batch Mixing Plant LB Series

Asphalt Batch Mixing Plant LB Series

view detail

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.